The Future for High-Power, High-Reliability Automotive Electronics

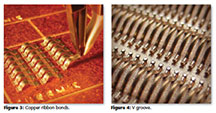

Wedge bonding is widely used for interconnection of automotive engine control modules and other under the hood devices. Large diameter aluminum, copper round or ribbon wire are commonly used because of the high current that many of these devices require. Bonding large diameter wire and ribbon requires a lot more energy than bonding fine wire. The dynamics are also different as wire is stiffer and significant forces are applied to both the first bond and the underlying metallization while bending the wire during looping. Wedge bonders can bond both ribbon and round wire on the same platform with only a minor changeover. Heavy wire wedge bonders can bond both round bonding wire of up to 20 mils diameter and ribbon up to 80 mils width x 12 mils thick.

Wedge bonding is widely used for interconnection of automotive engine control modules and other under the hood devices. Large diameter aluminum, copper round or ribbon wire are commonly used because of the high current that many of these devices require. Bonding large diameter wire and ribbon requires a lot more energy than bonding fine wire. The dynamics are also different as wire is stiffer and significant forces are applied to both the first bond and the underlying metallization while bending the wire during looping. Wedge bonders can bond both ribbon and round wire on the same platform with only a minor changeover. Heavy wire wedge bonders can bond both round bonding wire of up to 20 mils diameter and ribbon up to 80 mils width x 12 mils thick.

Download the full article below which includes a detailed discussion about large diameter wedge bonding for automotive applications. This article about wedge bonding was published in the July 2012 issue of SMT Magazine.

| Attachment | Size |

|---|---|

| SMT-July2012_WedgeBondingforAutomotive.pdf | 1.79 MB |

Large Diameter Wedge Bonding of Round and Ribbon Wire: The Future for High-Power, High-Reliability Automotive Electronics

Large Diameter Wedge Bonding of Round and Ribbon Wire: The Future for High-Power, High-Reliability Automotive Electronics